Jeff Hohlstein's WP&YR

Modeling realistic operations on the WP&YR

Please allow me to introduce my passion, the guiding hobby premises, my WP&YR fleet and myself. Three years ago my wife Jodi, said, “You need a hobby.” Flying had been my hobby but the demands of our business precluded me from keeping up with it. I’ve always had a penchant for detail. As a teenager, everybody else had Lionel trains, I insisted on an American Flyer (S scale, now out of business). I decided to model in HO because of the detail. However, a distant cousin, in a half-hour conversation, convinced me that there was nothing headier than running realistic operations with multiple trains if one was to be a modeler. He also pointed out how much ready to run (RTR) equipment was available in HO so it could also look good.

At the same time I began growing to love the WP&YR, because of its brash beginnings and how it opened up the Yukon. The equipment had ‘character’ like none other in the world. Quickly I learned that ‘none other’ included producers of HO equipment.

My passion is to conduct realistic operations of the WP&YR on an HO scale layout that models Skagway, Shops, Pitchfork Falls, Tunnel Mountain, White Pass Summit, Bennett, Carcross, MaCrae Station, Utah Station and Whitehorse. It’s to operate in the 1970’s, with up to four trains running at any given time. This is my hobby’s mission. It places emphasis on operational capability and eventually will have 75 to 100 pieces of equipment.

Guiding premises: Quoting from Dave Frary in How to build realistic Model Railroad Scenery, 2nd Edition (Kalmbach Books, © 1998), “Regardless of how much thought we put into it – and how hard we try – this business of making model railroad scenery is at best a matter of building an effective caricature of real landscape. To some extent, every model railroad ends up looking like a Hollywood movie set…If done well, the scene is both convincing and easily recognized.”

True to developing an operating layout, I first did the Operating Analysis and Shippers’ Directory published previously. That, combined with available space, drove the layout design. To get to my operating passion in HOn3 as a Finescaler would take far more time and resources than I can muster. Therefore, I’ve made a few decisions about scale accuracy. I chose HO because of track infrastructure and equipment availability and reliability. I chose scratchbuilding from plastic and wood because of the lack of WP&YR equipment available in HO. Track gauge aside, where possible, I’ll get to the finest detail I can using these media. While the scale accuracy of scratchbuilt plastic doesn’t compare to brass, it looks good for all but the very finest detail close-ups. And those close-ups miss the action of an operating railroad. Eventually, my model will use 24 Anvil ore container kits, purchased from Markus Zoschg. I’m very interested in the other kits he is producing. Except for the coaches, each car will not necessarily be an exact replica of a specific prototype car, rather a replica of a class of cars, decaled to specific numbers. The coaches will be individual prototype replicas. I believe this approach is consistent with Dave Frary’s advice.

My WP&YR fleet has been in production for three years and it is just now getting to the point of limited operations at Shops. Let me introduce the gang:

Figure 1-1: - The line-up:

Clockwise from the left, background: Turnaround loop; five Model Power coaches awaiting modification; Lakes Tagish; Kluane and Spirit; Refueling station (must be rebuilt to WP&YR design) and oil tanks; No 73, as sold to me by White Pass Train Shoppe; Shops building still under construction; Alco’s 101, 109; Alco 110; GE 81

Figure 1-2: - Number 101:

The first Alco 100 Class to be almost completed. It still needs its horns and that crazy antenna on all WP&YR locomotives. Above the trucks, 90% of what you see is from scratch. There were no detail purchase parts available to simulate the heat exchangers, topside doors, front hood, running board (deck), ladders, rails and hose assemblies in the HO world.

Figure 1-3: - 101 Started as an RSD4/5:

This image shows the comparison after all the hood work was done and before starting on the deck assembly and associated equipment.

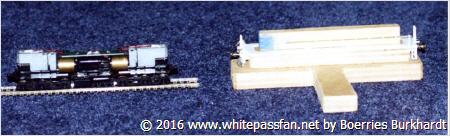

Figure 1-4: - Nose weight:

The RSD 4/5 has large weights under both the front and rear hood (pictured). The front one had to go. I added smaller lead weights in the cab to make up. I lost an ounce of weight in the process, and any loss of performance was not easily discernable. Also pictured, the Alco 101 deck sits in its construction jig.

Figure 1-5: - Operational test bed:

This was a functional mock-up to see if I could go with the redesigned wider ladders. The test showed interference with the trucks, so I had to go with the older style ladders.

Figure 1-6:

The “Boss” Engine #81 is the yard “Boss” for Shops. It’s awaiting its decals (on backorder) which have to be applied before installing the guardrails and finishing details. This model started out as an Athern SW/1500 diesel switcher.

About me: I flew fighters in the U.S Navy for 20 years. I was flying F-4B Phantoms from the decks of the USS Enterprise in the Mediterranean before my 21st birthday. Flew my first and last Navy jets in the same squadron. The first, a basic jet trainer in VT-7, Meridian, Mississippi as a student naval aviator. My last, in the same squadron which I then commanded, was in an advanced jet trainer, the TA-4J Skyhawk. I have about 2500 pilot hours in the Phantom, 700 pilot hours in the F-14A Tomcat, and exactly 800 aircraft carrier landings.

I worked for Lockheed as a project coordinator, project manager, quality engineering manager and director of product assurance. Much of what I learned about manufacturing full scale aircraft, has been applied to my model building.

I am now an executive search consultant (industry recruiter of automation and special machines technical, managerial and sales professionals).

What next? I’ve learned a lot about plastic and to some extent wood scratchbuilding. I want to share these lessons, because many techniques cross scale and in some cases work for differing primary objectives. What goes out comes back. I hope my work encourages other modelers to share their secrets. I learned a lot from building the first two Anvil containers. I couldn’t have done them justice without Dieter’s wonderful article.

My next article will be about getting into scratchbuilding: Helpful publications, differences between plastic in factory models and scratchbuilding supplies; cutting and bonding materials. May your rails lead to fun and success.